Portfolio

Spring Loaded Knee Brace

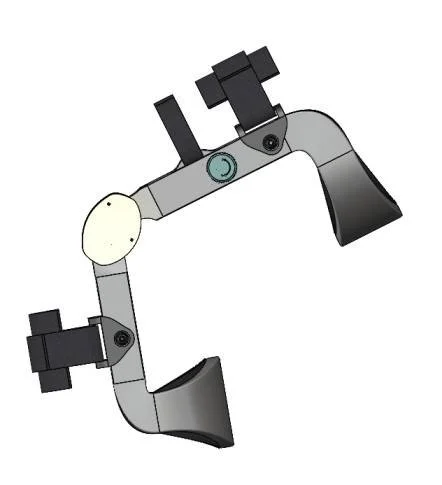

Spring Loaded knee brace is a medical device designed to support and protect the knee and is used for treating knee injuries and helps to relieve the pain in chronic conditions like arthritis.

This case study is made to resolve the problem that was identified in my research. The best way to solve the problem is to first identify and define the problem.

Here is the Problem: Knee brace require a mechanism that should use the spring force for levitation and this spring assistance can be adjusted precisely as the patient chooses to have without compromising the full range of motion of the knee joint.

Initial Brainstorming and design sketches were made to understand and to illustrate the mechanics. Analyzed if this mechanism is solving the problem defined. Sketches shows the preliminary understanding of how the product should look like so I prefer to draw them by hand.

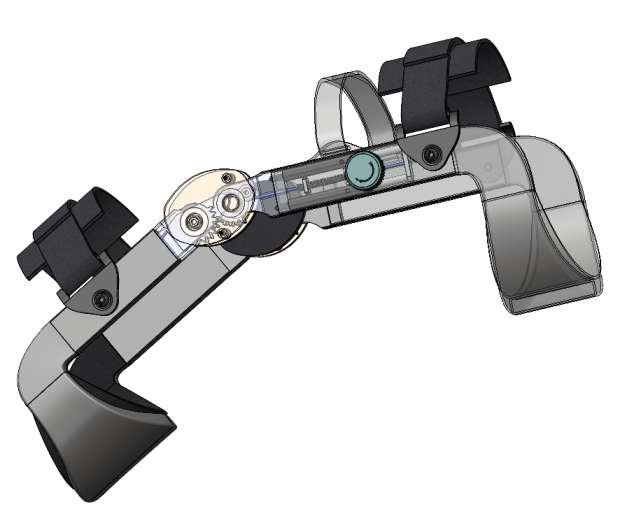

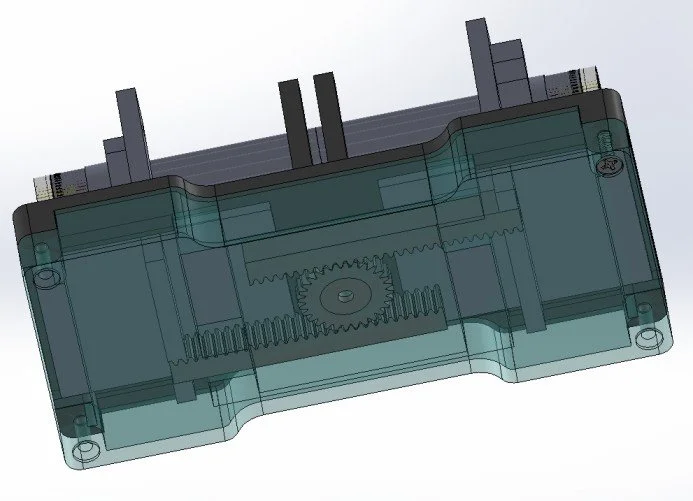

Product design and modifications were completed, and I did a final refinement to document the product is meeting the design intent specified and furthermore dive deep into the detailing of the design. Entire product is designed keeping the patient comfort in mind. A unique mechanism is incorporated to precisely control the spring force output by adjusting the controller mounted on the side of the brace. This allows the patient to adjust the spring assistance as they wish to have and this can be done even when they are sitting on the chair and without even compromising the range of motion which the patient loves to have.

Gallery

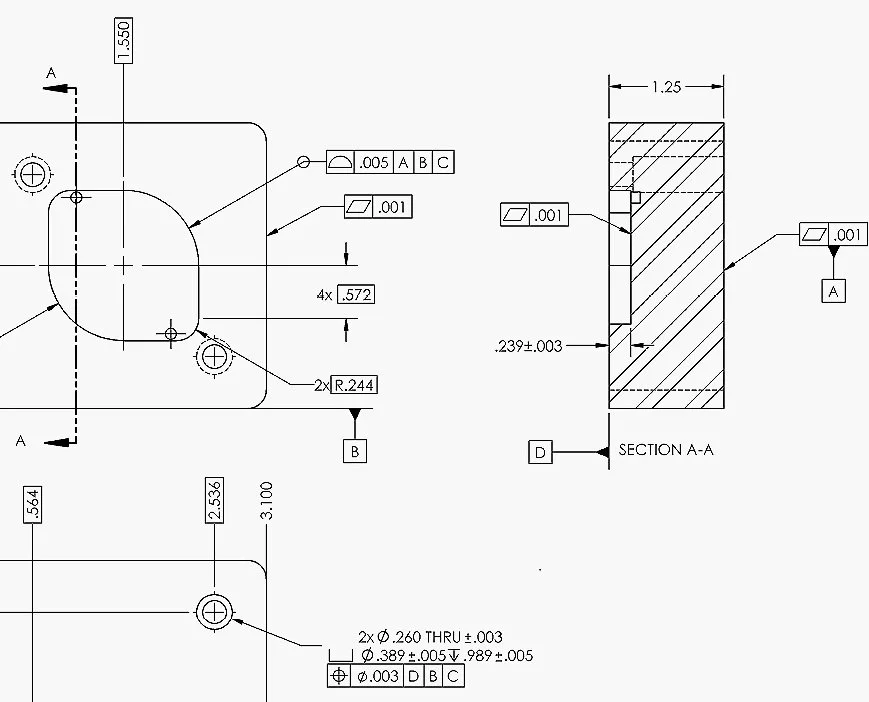

2D drawing for Manufacturing and inspection. GD and T

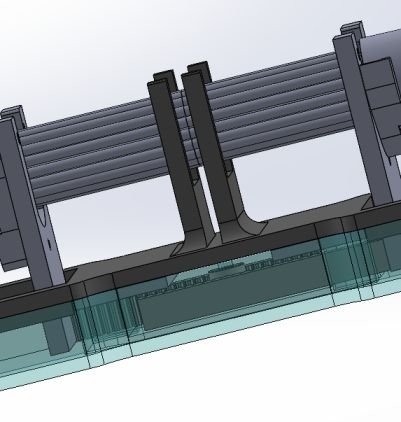

A fixture made to locate the center of the cable with two connectors on both ends. Originally, It was taking so long and difficult for operators to identify the cable center using the ruler (to take measurement and identify the center) and operators were holding the cable with one hand and ruler on the other hand, involving markers and other stuff. Using this fixture, personal can identify the center easily without having to use any rulers or measurement devices and cut the cable precisely at the center with the assistance of the guides. This is entire made of off the shelf plastics and custom 3D printed parts.